Many times we have seen or heard about clean rooms, maybe without knowing it. They are the typical rooms that appear in movies or documentaries where people put on special suits and decontaminate themselves before entering. Let’s find out more about these facilities!

Clean room concept

A cleanroom is an enclosed space that allows extremely low levels of contamination to be maintained.

The environment inside this type of rooms is under rigorous control systems, the main parameters that are controlled are:

- Lighting.

- Geometry and interior finishes.

- Number and dimensions of particles in the air.

- Dry temperature and its distribution.

- Humid temperature and its distribution.

- Air flow: speed and direction, as well as its distribution in the room.

- Indoor air pressure and its distribution.

- Fire protection.

- Electrostatic protection.

Although in general, a clean room fits this definition many times. In many cases, clean rooms are also considered to be those which, although they are not as demanding in terms of air purity, have very strict requirements in terms of the absence of electromagnetic fields.

In addition to the clean rooms themselves, this type includes spaces where machinery that is very sensitive to this type of interference is used, such as X-ray rooms, magnetic resonance rooms, high-voltage wiring rooms, etc.

Origins

The first clean rooms, although they were not really clean rooms, began to be developed in the healthcare field at the end of the 19th century. At that time, microbiologists and surgeons realized that infections, at least those caused by bacteria contained in the operating room air, were considerably reduced when there was intense ventilation.

It also demonstrated the need to sterilize surgical instruments and to apply certain standards of dress and hygiene to the users of the room.

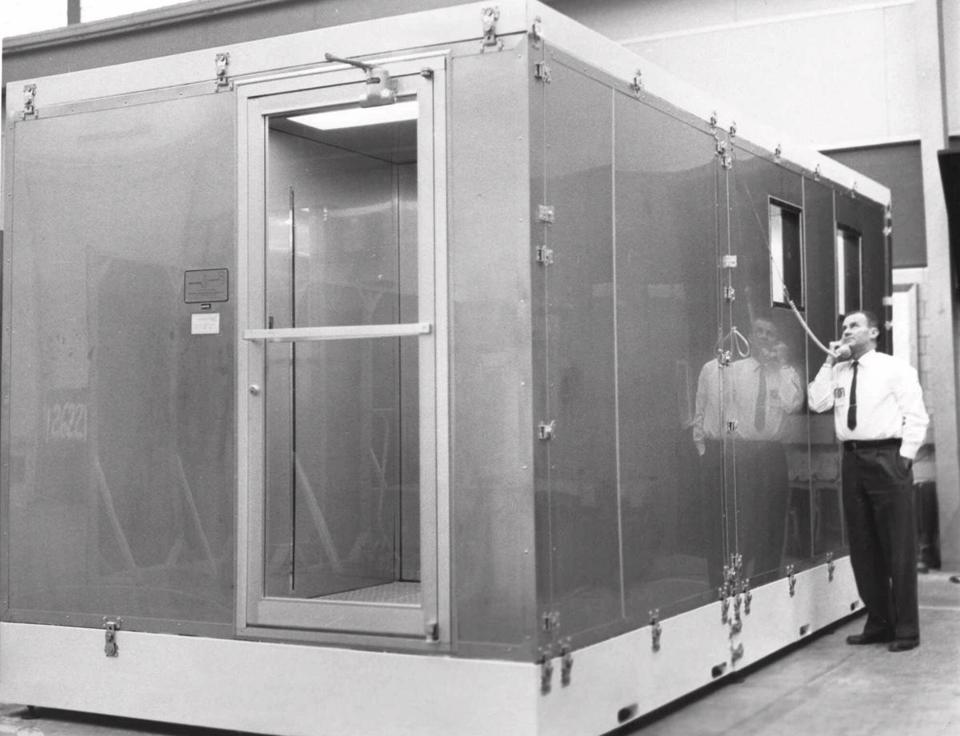

The first modern clean room was designed by Willis Whitfield (December 6, 1919 – November 12, 2012), an American physicist, in 1960. His main innovation consisted of integrating a constant flow of highly filtered air into the room, which expelled impurities to the outside.

Cleanroom applications

This type of installation is used in industries whose processes require impurity-free air. They are very common in the development of microelectronic products and in the pharmaceutical industry, although they are also used in areas such as:

- Micromechanisms.

- Optics.

- Biotechnology.

- Medicine.

- Food.

It should be noted that although we have two rooms with the same classification, depending on their dimensions, field of application, workload, etc., specific materials and technologies will be used.

Characteristics and classification of cleanrooms

There are different standards for the classification of these spaces, such as ISO 14644-1 or FED-STD-209E, which group them into classes according to the number of particles in the air.

| Class | Maximum number of particles/m3 | |||||

| ≥0.1 µm | ≥0.2 µm | ≥0.3 µm | ≥0.5 µm | ≥1 µm | ≥5 µm | |

| ISO 1 | 10 | – | – | – | – | – |

| ISO 2 | 100 | 24 | 10 | – | – | – |

| ISO 3 | 1,000 | 237 | 102 | 35 | – | – |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | – |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | – |

| ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 |

| ISO 7 | – | – | – | 352,000 | 83,200 | 2,930 |

| ISO 8 | – | – | – | 3,520,000 | 832,000 | 29,300 |

| ISO 9 | – | – | – | 35,200,000 | 8,320,000 | 293,000 |

The values in the table are cumulative. For example, in a class 3 room the 237 particles in the 0.2 µm column also include those of a larger size. On the other hand, values that are not shown in the table are either so low that they are not reliably measurable or are so high that it is not worthwhile to set a limit.

A class 9 room corresponds to an ordinary room without any special air filtering system.

Air flow in a clean room

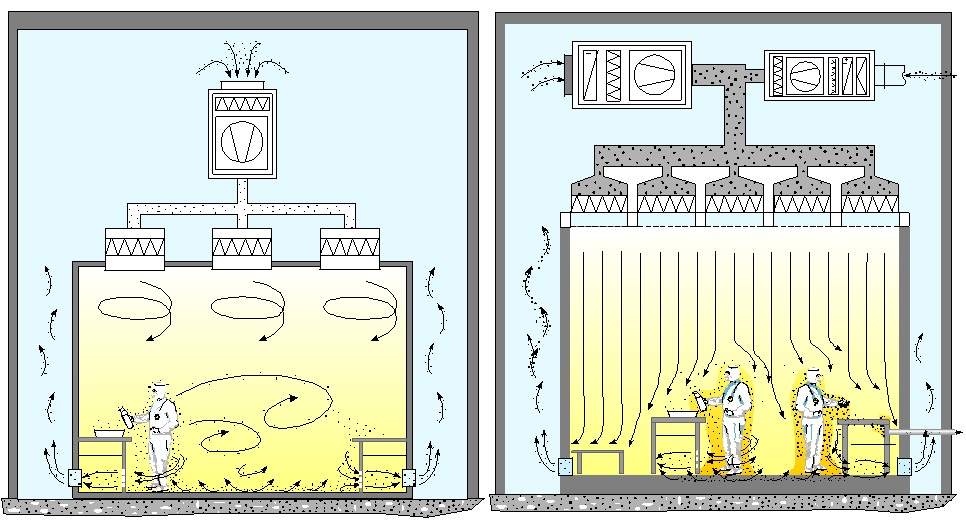

In clean rooms there is a constant flow of highly filtered air, which we can differentiate according to the type of air movement into turbulent and laminar.

In a turbulent or multidirectional air flow, the degree of purity is achieved by “diluting” the contamination through the supply of clean air.

On the other hand, in a room with a laminar or unidirectional airflow (whether vertical, horizontal or inclined), the air flows uniformly through the room so that contamination is eliminated without the possibility of it spreading.

Regardless of the type of linking flow, we can differentiate between open and closed loop systems. The latter are very common, for example, in processes where toxic substances are used.

Other factors to consider

Although the ventilation system is critical to maintain room decontamination levels, there are other points to consider.

Personal contamination

Undoubtedly one of the main sources of microorganisms in a cleanroom are the cleanroom users themselves. For this reason, in most cases, appropriate clothing should be worn that is used exclusively inside the room.

Humidity levels and static electricity

It must be kept constant between 40%-60% so that static electricity is not produced. At the same time, there should be no condensation at any time.

In addition, the installation must have a ground network independent from that of the rest of the building with a very low resistance where all electrical devices, furniture, etc. will be connected.

Temperature

The temperature of the room is determined by the type of activity that takes place in it. Temperature tolerance is very limited, in certain industries it can be as low as ±0.5°.

The requirements in terms of temperature control and stability demand that the cooling/heating, control and regulation systems, in addition to the insulation of the room itself, be of the highest performance.

Lighting in clean rooms

As in any other space, lighting must provide the necessary amount of light for the activities to be carried out. Since the processes carried out in these rooms usually require a high degree of precision, a quality lighting system is essential.

Unlike other types of installations, the lighting of a clean room represents a very small part of its costs, both in terms of installation and commissioning as well as maintenance and energy consumption.

The difficulty in designing the lighting system is imposed by the often limited space left for the luminaires. Depending on the type of room, the surface occupied by the ventilation system usually takes up more than 90% of the available space.

Finally, luminaires with a high color rendering index are highly recommended, as they do not distort colors.

For all these reasons, LED lighting is the most recommended option. Its design is very adaptable, it is extremely efficient and the quality of light is very high.

Non-magnetic LED panels

An excellent option to illuminate hospitals, laboratories or spaces where the processes to be developed limit the presence of electromagnetic fields are non-magnetic LED panels.

These are characterized by being built with materials that do not interfere electromagnetically and whose driver is perfectly shielded. On the other hand, they have a very high LED performance and reduced glare factor (UGR).

Now we know a little more about what clean rooms are and what they are usually used for.

//